Magnetic Partical Inspection

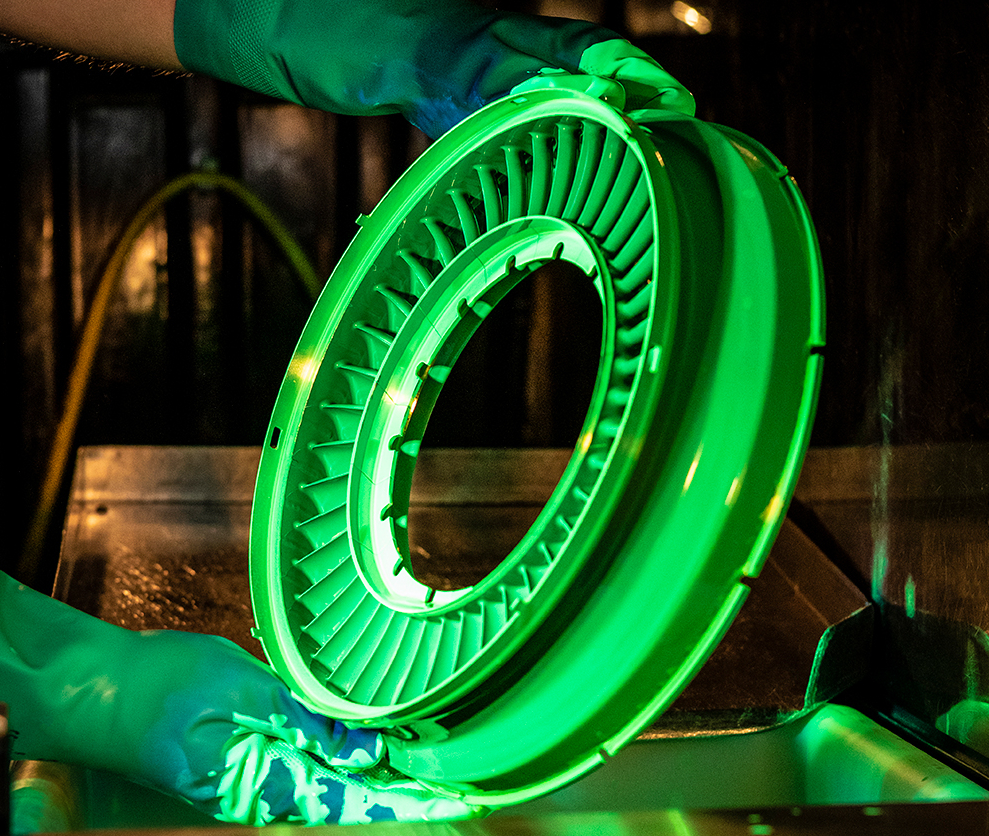

A magnetic field is created by any electrical current. Magnetic fields have the ability to cause ferromagnetic materials to move. The classic experiment with a bar magnet and iron filings demonstrates this. We generate a magnetic field inside the component under test using an electrical current in MPI. Inside the component, the magnetic field follows a specific pattern. Discontinuities (cracks, inclusions, etc.) change this pattern, causing the magnetic field to escape the component unexpectedly.

We attach fine magnetic particles to the surface of the component while applying the current in an oil-based carrier fluid. Particles are carried along with the fluid as it passes over the component and accumulate around the point where the magnetic field exits the part. A fluorescent coating is applied on the particles themselves. Inspecting in the dark with UV light provides the best contrast and the best likelihood of spotting the brilliant indicators generated by the process to discover faults. Surface breaking and somewhat sub-surface faults can be detected using this method.

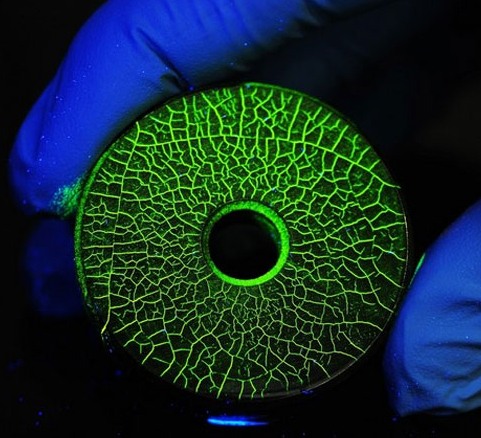

Penetrant Inspection

The penetrant process is divided into several steps, with the exact method varying based on the product's shape and the faults sought. Cleaning and dyeing are the first steps in the process. The dye seeps into any potential flaw that is visible on the surface. The dye is extensively applied to the part surface for good coverage, thus the next step is to remove the 'bulk' dye. This can be done by either washing or cleaning with a solvent. If the wash process involves water, the part may need to be dried before development. A hot air oven is typically used for this process. The process of development entails pulling the dye from any existing discontinuity and cementing it in place. This can be done in a variety of ways, but the most frequent is with a dry chalky powder. The final and most important stage is inspection. The operator manually inspects the part for bleed out of the dye 'indications.' Because the dye shines brilliant green under UV light in fluorescent approaches, observation in the dark with a UV lamp creates a natural contrast. This offers the inspector the best possibility of finding the signs and detecting any flaws.